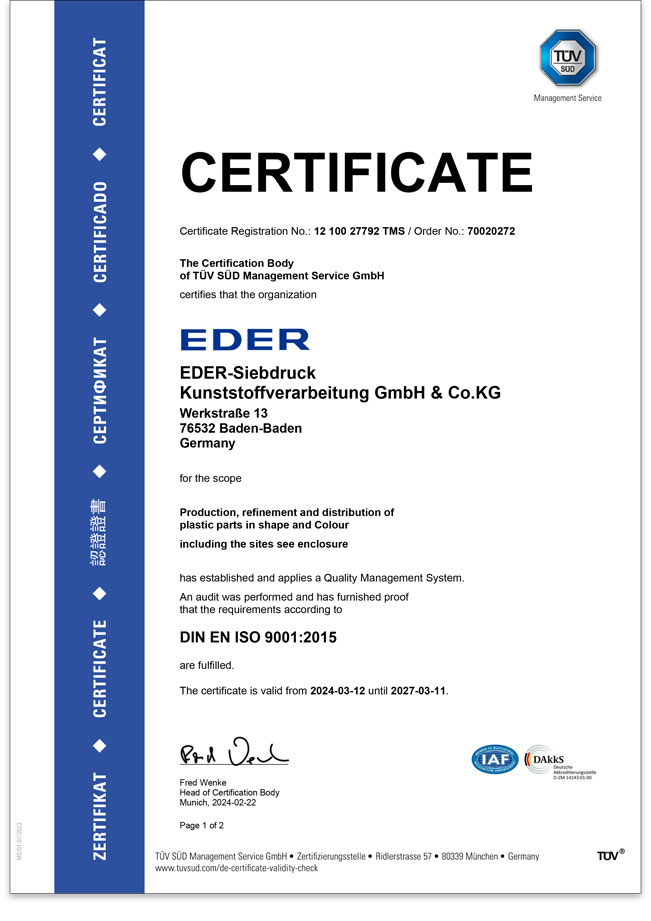

We have been manufacturing high-quality plastic control panels for 50 years, primarily for the electrical and household appliance industry.

The satisfaction of our customers drives us every day anew.

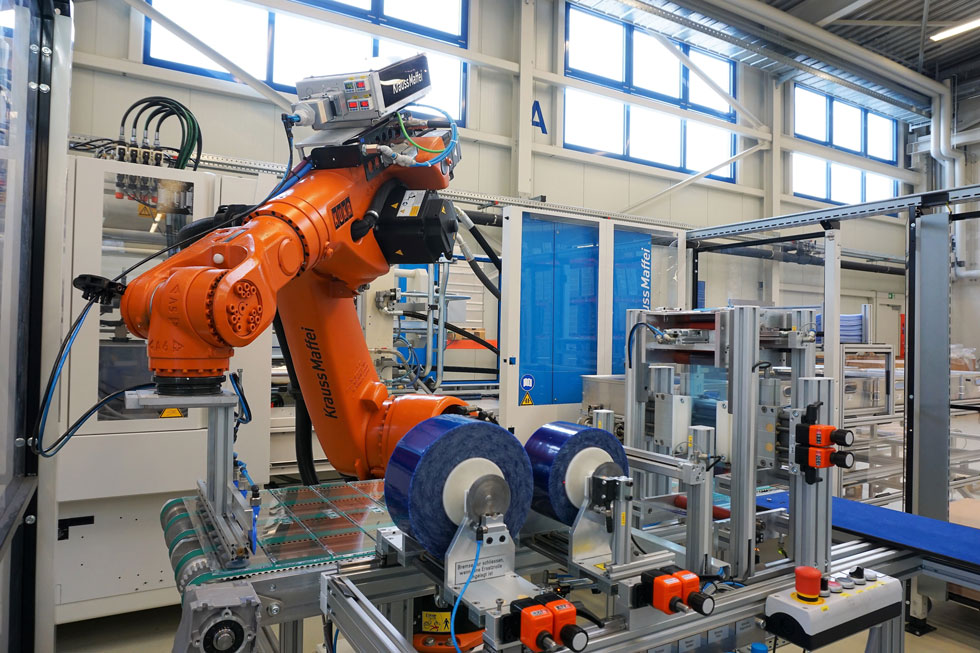

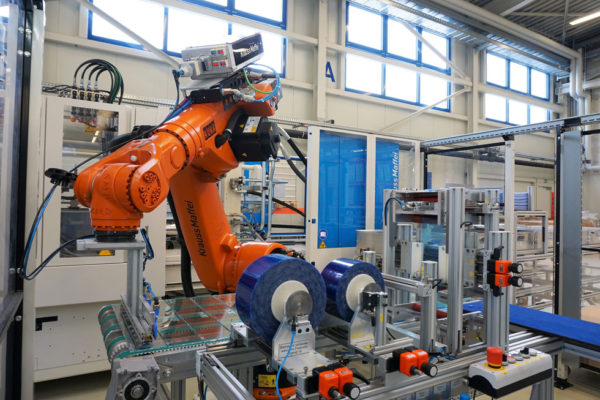

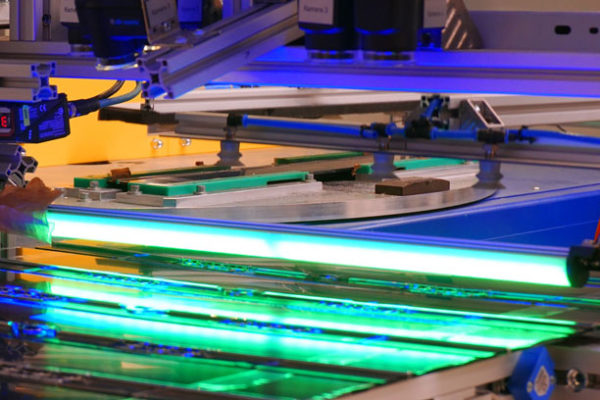

High quality is the result of technical expertise and experience, precise manufacturing and constant innovation.

Many of the products manufactured in our company can be found in the display and control panels of household and electrical appliances, such as dishwashers, stoves, ovens and coffee machines.

We are happy to support you in solving your specific task.